Exploring the impact of Altium Auto Route in modern automotive technology unveils a world where efficient PCB design plays a crucial role. From revolutionizing manual routing to optimizing automotive electronics, Altium Auto Route is at the forefront of innovation.

Overview of Altium Auto Route

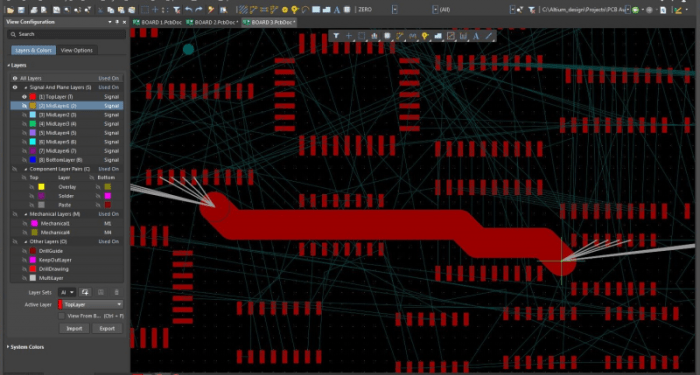

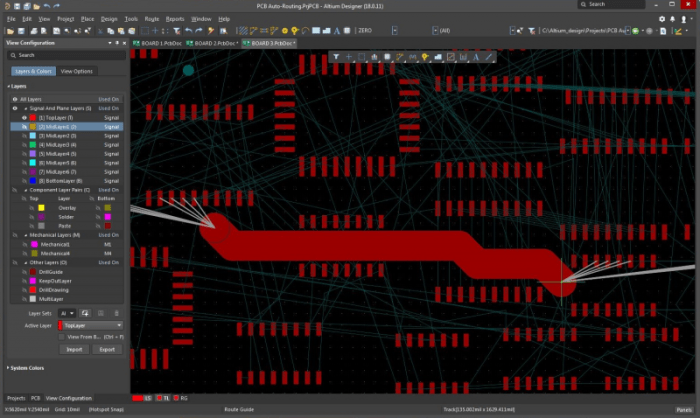

Altium Auto Route is a feature in PCB design software that automates the process of routing connections between components on a printed circuit board. This tool uses algorithms to determine the most efficient pathways for electrical signals, saving time and reducing the likelihood of errors in the design process.

Efficiency of Altium Auto Route

- Altium Auto Route differs from manual routing by allowing designers to input design constraints and preferences, such as signal integrity requirements and component placement rules, before automatically generating the routing paths.

- Manual routing requires designers to manually trace connections between components, which can be time-consuming and prone to human error.

- By automating the routing process, Altium Auto Route can optimize signal paths for minimal interference, reduce signal delays, and ensure that the design meets all necessary specifications.

Application of Altium Auto Route in Automotive Technology

In modern automotive electronics, Altium Auto Route plays a crucial role in optimizing the design and functionality of PCBs for various automotive applications.

Improved Routing Efficiency

- Altium Auto Route software automates the routing process, allowing designers to quickly create efficient and optimized PCB layouts for automotive electronic systems.

- By automatically determining the best routing paths based on design constraints and rules, Altium Auto Route helps reduce signal interference and improve signal integrity in automotive PCBs.

Enhanced Design Accuracy

- Altium Auto Route ensures precise routing of traces and connections on automotive PCBs, minimizing the risk of errors and ensuring the reliability of the final electronic system.

- With advanced algorithms and design rules, Altium Auto Route helps designers achieve high-quality PCB layouts that meet the stringent requirements of the automotive industry.

Time and Cost Savings

- By automating the routing process and streamlining design iterations, Altium Auto Route helps automotive engineers save time during the PCB development phase, leading to faster time-to-market for new vehicles and electronic components.

- Additionally, the use of Altium Auto Route results in cost savings by reducing the need for manual routing and minimizing the chances of costly design errors or rework.

Challenges and Limitations of Altium Auto Route in Automotive Design

When it comes to utilizing Altium Auto Route in automotive PCB design, there are several challenges and limitations that engineers may encounter. Understanding these obstacles is crucial for optimizing the tool and achieving efficient results in automotive technology applications.

Common Challenges Faced with Altium Auto Route

- Routing Complex High-Speed Signals: Altium Auto Route may struggle with routing intricate high-speed signal paths in automotive PCBs, leading to signal integrity issues.

- Component Placement Constraints: The tool may face difficulties when dealing with tight component placement constraints common in automotive design, affecting routing efficiency.

- Interference and Crosstalk: Automated routing tools like Altium Auto Route may not always effectively manage interference and crosstalk challenges in automotive electronics, impacting overall performance.

Limitations of Automated Routing Tools in Automotive Electronics

- Adaptability to Changing Design Requirements: Automated routing tools may lack the adaptability needed to quickly adjust to evolving design requirements in the fast-paced automotive industry.

- Complexity of Multilayer PCBs: Handling the complexity of multilayer PCBs in automotive electronics poses a challenge for automated routing tools like Altium Auto Route, especially when dealing with power distribution and signal routing.

- Optimization for EMI/EMC Compliance: Ensuring electromagnetic interference/electromagnetic compatibility (EMI/EMC) compliance can be challenging with automated routing tools, as manual intervention is often required for precise control.

Strategies to Overcome Limitations and Optimize Altium Auto Route for Automotive Applications

- Manual Routing for Critical Paths: For critical high-speed signal paths, consider manual routing to ensure optimal signal integrity and minimize interference issues.

- Iterative Design and Simulation: Implement iterative design processes combined with simulation tools to validate and optimize the PCB layout generated by Altium Auto Route for automotive applications.

- Custom Rules and Constraints: Define custom design rules and constraints tailored to automotive design requirements to enhance the performance of Altium Auto Route in routing complex PCBs.

Best Practices for Utilizing Altium Auto Route in Automotive PCB Design

When it comes to leveraging Altium Auto Route for automotive PCB design, there are key factors to consider in order to optimize efficiency and performance. By following best practices, you can achieve optimal results in your automotive applications.

Consideration of Signal Integrity

- Ensure proper signal integrity by setting constraints for critical traces.

- Maintain controlled impedance for high-speed signals to prevent signal degradation.

- Use differential pair routing to reduce crosstalk and maintain signal integrity.

Optimizing Routing Efficiency

- Group components logically to minimize trace length and reduce signal interference.

- Utilize routing topologies that minimize EMI and signal cross-talk.

- Implement layer stack management to optimize signal routing and reduce noise.

Utilizing Design Rule Checks (DRC)

- Run regular DRC checks to ensure compliance with design rules and constraints.

- Address any errors or violations detected by the DRC to maintain design integrity.

- Utilize Altium's DRC feature to enforce design rules and optimize PCB layout.

Closing Summary

In conclusion, Altium Auto Route stands as a cornerstone in modern automotive tech, driving advancements and pushing boundaries. Its role in streamlining PCB design processes and enhancing automotive technology is undeniable, setting a new standard for efficiency and performance.

Query Resolution

What are the key differences between Altium Auto Route and manual routing?

Altium Auto Route automates the routing process, saving time and ensuring consistency, while manual routing requires manual intervention and decision-making.

How does Altium Auto Route contribute to enhancing automotive technology?

Altium Auto Route optimizes PCB design in automotive electronics, leading to improved performance, reduced errors, and faster time-to-market for automotive products.

What are some common challenges faced when using Altium Auto Route in automotive PCB design?

Common challenges include handling high-speed signals, managing complex layouts, and ensuring signal integrity while using automated routing tools.

How can Altium Auto Route be optimized for automotive applications?

Optimizing Altium Auto Route involves understanding the specific requirements of automotive PCB design, fine-tuning routing parameters, and implementing best practices for efficient routing.